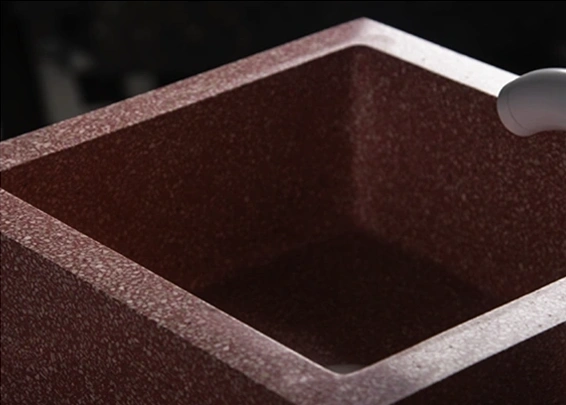

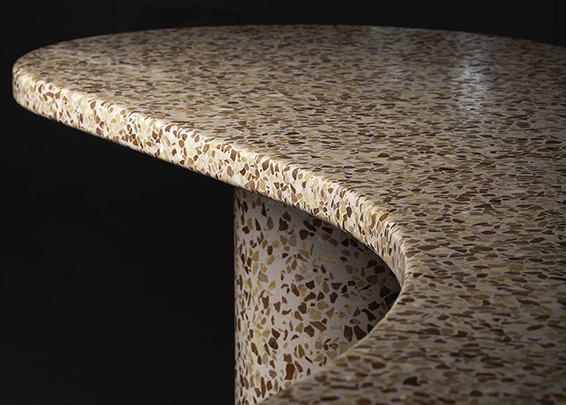

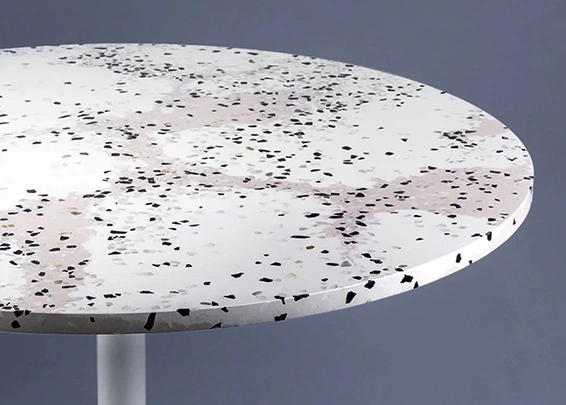

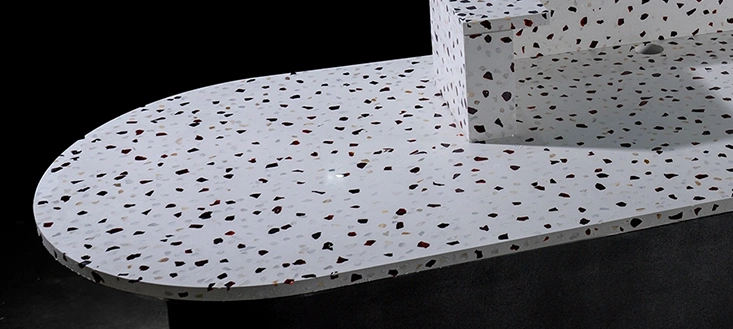

Sinks and basins

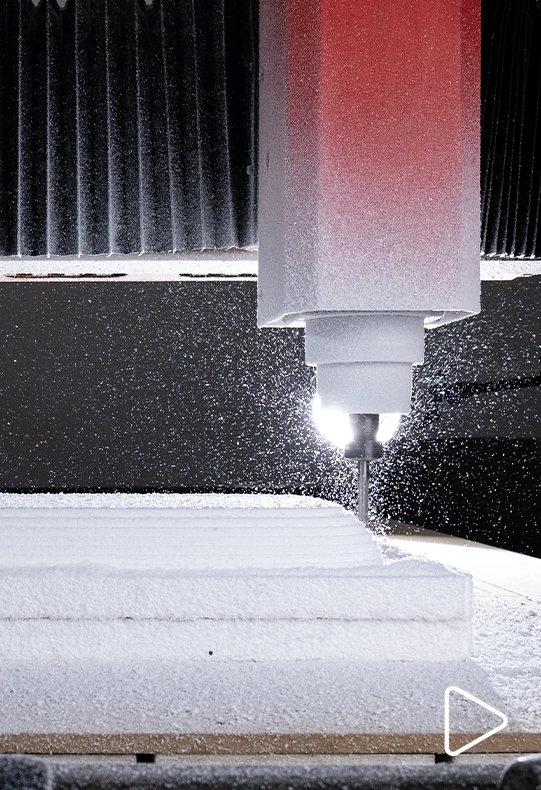

Custom-made washbasins, sinks and shower trays tailored to your design. High-quality craftsmanship for timeless, functional, and beautiful interiors. Shaped in ESTEZZA®, our in-house Terrazzo collection or in CREATZO®, a unique UHP concrete.

Specifications to consider +44 (0) 203 514 0483

+44 (0) 203 514 0483