TECHNICAL SHEET

TECHNICAL SHEET

Important : Furniture and elements in Terrazzo are custom manufactured, individually, at our facilities in Tangier (Morocco). The pieces are often heavy and bulky.

Your project should be managed by a professional – fitter, decorator, architect, entrepreneur, who will take care of measurements on-site, unloading, manipulation and final adjustments and repairs of the parts during installation. This professional will be our client and the contact person for our technical team.

Complexity of custom production requires us to only accept projects with a value greater than £3000, or included in a global order MOSAIC FACTORY’s tiles.

By making the payment, the end customer validates the measurements of the plan and details of the production / quote sheet. He confirms having read that "technical sheet" and understands the characteristics of Terrazzo and Granito materials.

Production : The production stages are: exchanges of information between the client and our design team until validation of the execution plan | mould making | metal or fibber reinforcements | casting of materials | natural hardening in a controlled atmosphere for a few eeeks | 2D and 3D polishing | surface finish | application of Sealer.

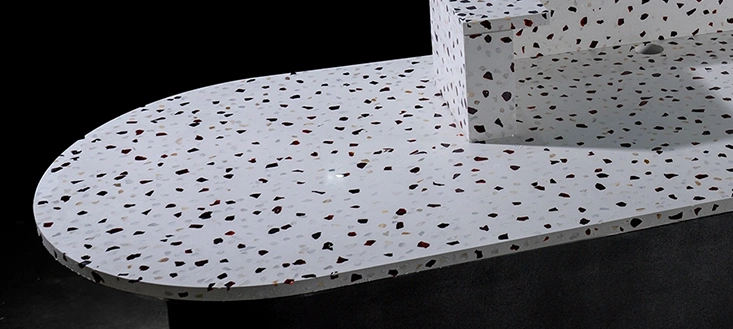

Terrazzo can be cast in large pieces, whether in simple flat moulds or complex 3D volumes. We have all the IT tools - CAD, CAM and computer numerical control machines (CNC machine) - and teams trained in their use.

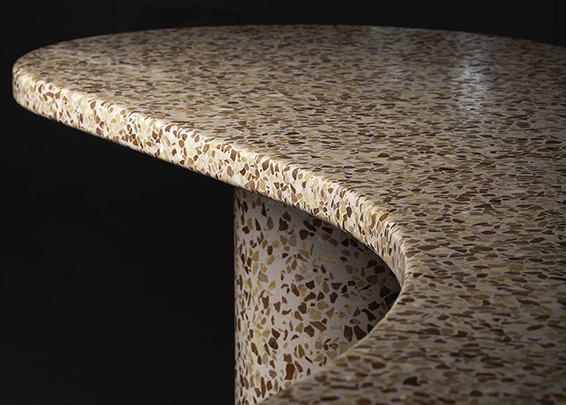

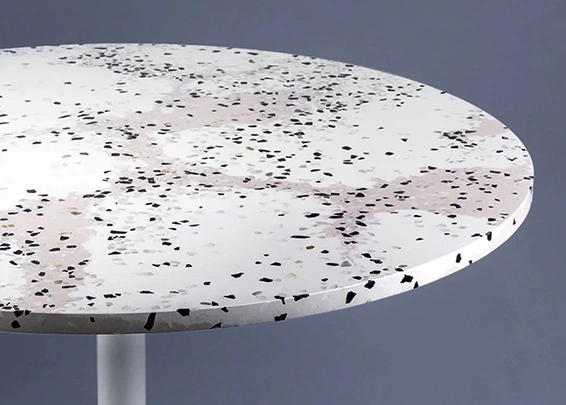

The Terrazzo textures are fully customizable, in colour, shape and size of marble aggregates.

The different elements are shipped to your site on a pallet, with protective packaging such as a "sea crate".

The products will be transported to a site freely accessible by a delivery truck. The professional in charge of the project must take care of the unloading of the packed parts / their unpacking / the movement to the site or to the upper floors / the adjustments, repairs and rectifications of the parts, necessary for the installation. Our mission is only manufacturing the parts in accordance with the execution plan.

Definition : Terrazzo is a kind of concrete, manufactured with care and quality additives. It is a mix of white cement, fine aggregates (powder and micro-granulates) and chips, fragments of pieces of Marble or other mineral materials. After adding water, this mix is poured in a mould, and left to harden naturally for several weeks. The next step is abrasive polishing, that eliminates a 2-5mm surface layer and unveils the decorative aggregates. The terrazzo is gloss-polished which hardens the surfaces and enhances the colours. Finally, we apply a Sealler to limit porosity, penetration of stains and chemicals actions.

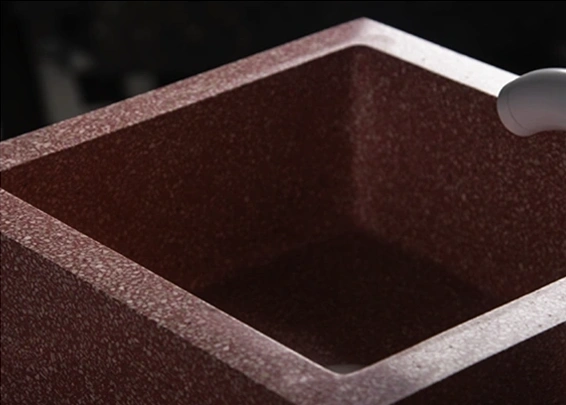

Granito is a fine-grained Terrazzo that incorporates chips of 2 to 3 mm, generally of marble or coloured glass. Granito is therefore more uniform than Terrazzo.

Terrazzo is a decorative material known since Roman times. Originally made with lime-based binders (baked limestone) then hydraulic mortars (adding volcanic ash and crushed bricks to the lime). The discovery of "Portland" cement (1860) allowed a wide distribution of Terrazzo as we know it today. Terrazzo is not a structural concrete but a decorative material.

Maintenance : Terrazzo (and Granito) are cement and marble-based materials, therefore alkaline in nature. The maintenance, porosity and durability of Terrazzo is similar to that of natural stone, marble, or polished concrete surfaces.

Worktops, tables and furnishings are treated in factory, after polishing: sealed, crystallized and waxed, in order to reduce their porosity and therefore their sensitivity to stains from pigments or chemical agents.

Regular care with PH-neutral soap and wax, and avoiding prolonged contact with acidic, alkaline or strongly pigmented products will ensure the long-term beauty. Terrazzo is a product that lives and evolves with time. This product should only be cleaned with PH neutral soap as other products may cause etching.

Handling and installation : Terrazzo slabs and furniture are to be installed by an experienced professional. Our responsibility is limited to the manufacturing of the Terrazzo elements and not their subsequent operations. Slabs should be kept in their packaging until installation to prevent any aesthetic or structural damage. The slabs must not rest or lean on their edges and sides to avoid chipping.

The weight of the slabs (between 70 and 95 kg per m2 for thicknesses of 3 to 4 cm) implies a need for detailed planning of installation, making sure structures are prepared and reducing handling of the slabs.

All movement and manipulation of the slabs prior to installation should be done vertically, and not horizontally. Make sure all supports, and structures are levelled before beginning installation.

Limitation of liability : The slabs, furniture and elements are manufactured according to the information in the execution plan approved by the client prior to order confirmation. We take no responsibility for any errors made by customer during the measurement process. The execution plan must therefore be carefully reviewed by the buyer. A dimensional tolerance of +/- 4 mm from the execution plan is to be considered normal, due to the retractions of concrete and the handcrafted nature of a bespoke manufacturing process. We offer a transport solution, but the customer can freely choose another logistics company. The slabs and objects are transported on pallets and delivered to the pavement on a street accessible to a 12T delivery lorry. The unpacking of the pallet / transport to site or to the upper floors is not included in our service.

+44 (0) 203 514 0483

+44 (0) 203 514 0483

TECHNICAL SHEET

TECHNICAL SHEET